If you can't read the pdf you can click here to download the PDF file

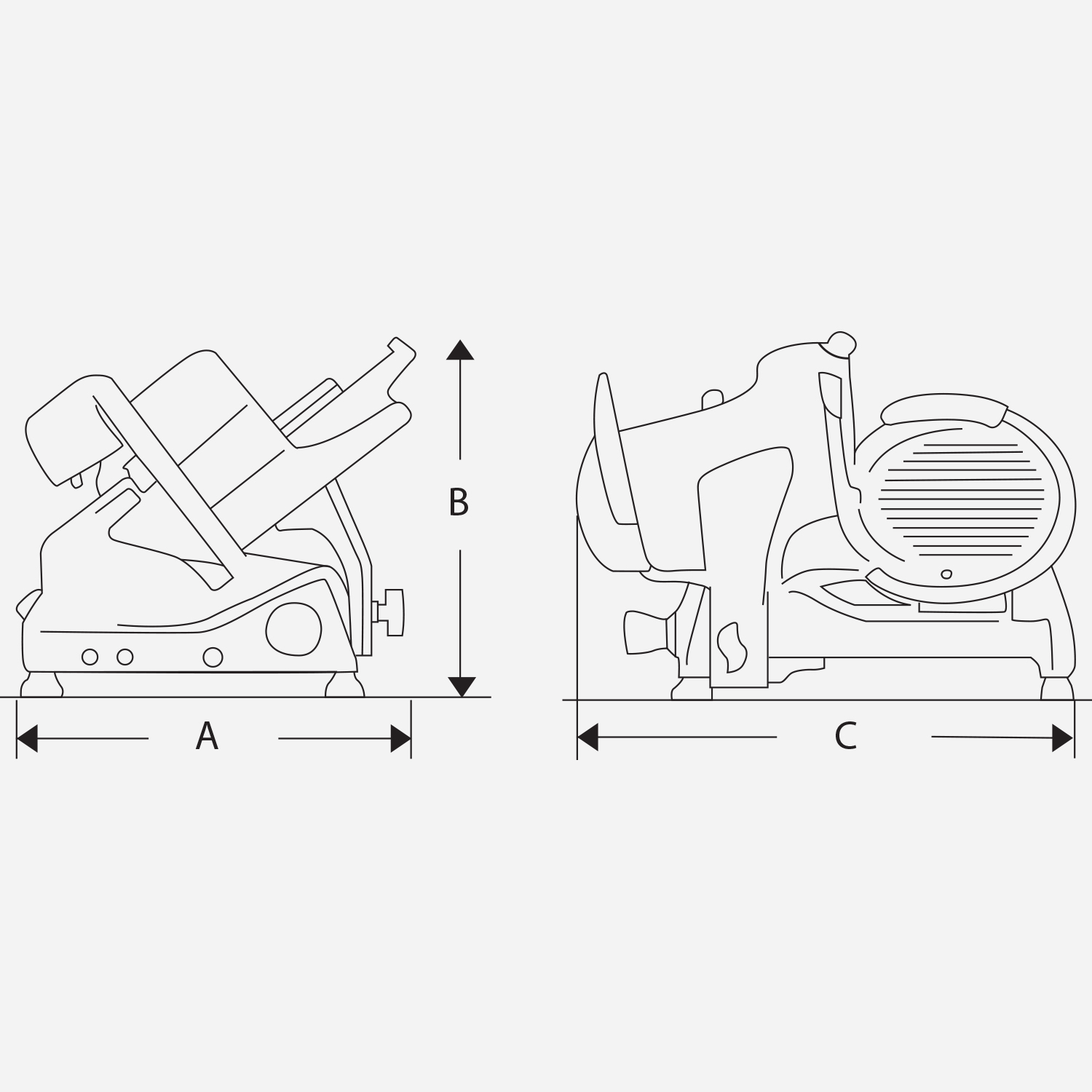

Suprema gravity slicer PEG315

Cod.Art. BKPLEGGL0100000000

This slicer, with its considerable cutting capacity, has been designed to fuse together ease of use with a significant reduction in friction.The model features a new and innovative design, rounded edges and soft and ergonomic spaces and shapes. 38° tray inclination is ideal for loading and unloading the product, and reduce operator strain. Berkel Supremais fitted with powerful and reliable motors, able to provide continuous service for high volume work loads. The quality of the blade and the precision assembly ensure cuts with very little waste and, therefore, important savings in the management costs of your business.

Suprema line is the top of the professional electric slicers range from Berkel. Designed and developed specifically for the MMR (Mass Market Retailers) the Suprema line can satisfy the needs of all the customers that, with no compromise, are looking for top slicing performance, highest safety standard and an easy of cleaning with no comparison in the category, to get easy of use and fast slicing operations with a related operational cost reduction. All the machines belonging to this product line have been designed to provide the best performance available on the market in every category. They combine the elegant design of all the Berkel slicers, made of smooth rounded lines, lack of hedges and high performance materials, with the best functionality. Nothing has been left to chance, every detail brings an operational benefit to the user. Suprema is available in all the technical configurations (Gravity, Vertical Salumeria, Vertical Macelleria and Delicatessen) with different blade diameter selection from 315mm to 370mm.

Performance

- 100Cr6 steel blade, the best on the market, for a perfect cut and for a longer lasting of the sharpening

- Increased baseplate thickness (for an overall machine weight between 40kg and 50 kg in the different versions) and stainless steel feet with anti slippery rubber inserts for total stability during slicing operations

- Gauge plate and blade cover with Superglide® technology to decrease product frictions and to avoid product warming for keeping the original taste

- 38 ° graded food plate to facilitate the passage of the material and the fall of the slice (on Gravity models)

- IP67 motor and watertight electrical box for a full protection from liquids during cleaning operations

- Gear box transmission to fully exploit the motor power for a perfect cut also with high density products

- Sliding bushing with Teflon treatment for and easy and increased slicing speed

- IP67 stainless steel fully sealed control panel and food-grade silicone gaskets on each exposed part

- Very thin residual product to minimize wasted material

- Wider food plate (340 mm) for a perfect positioning of every products

- Lock/Unlock food plate lever to easily position the product and to keep it fixed during slicing operations

- Gauge plate opening knob with 14 millimetric adjustment positions for an accurate regulation

- Gauge plate with an oblique 15 ° opening to facilitate the way out of the product while slicing (on Gravity models)

- Easy removable steel deflector

- Removable sharpener included with a single movement operating system to avoid sharpening mistakes by the operators

Cleaning and hygiene

- Aluminum alloy baseplate made out a single mold obtaining absence of gaps (not on 370 versions)

- Liquid collection tray integrated in the casting or inside the food plate for perfect hygiene and cleaning

- Inclined gauge plate drainer for clearing of liquids (on Gravity models)

- Removable stainless steel food plate and product press holder with stainless steel tacks for perfect hygiene and to speed up cleaning operations

- Wide space between blade and motor to facilitate and speed up cleaning operations

- Food plate lifting system to facilitate cleaning operations

Safety

- Complete closure of the gauge plate for maximum safety during cleaning operations and CE Block to prevent its opening when the plate is out of place

- Assisted product press holder opening system (on Vertical models) to prevent accidental release and for an easy product positioning

- Disarmed position of the meat press to prevent accidental release (on Gravity models)

- ON/OFF switches with high visibility LEDs

- Aluminum ring guard for increased safety

- Ergonomic controls in comfortable position to minimize operator efforts

- Stainless steel IP67 control panel with flush ON button to prevent accidental starting

-

Weight32 kg

-

Blade diameter315 mm

-

Electrical specs230V 50Hz 1PH 400V 50Hz 3PH 120V 50Hz 1PH 220V 60Hz 1 PH

-

Motor rating0,25-0,30kW

-

Blade material100Cr6

-

Cut thickness0 - 14 mm

-

Cut Capacity Circle198 mm

-

Cut Capacity Rectangular252x149 mm

-

DetailsGear transmission; metal handles, metal safety guard, frontal lubricating oil refill tank, Superglide® profile of the gauge plate with double wave, removable inox product holder

-

Removable partsslice guard deflector; Blade guard disk; meat table carriage

-

Sharpenerincluded, one-movement type

If you can't read the pdf you can click here to download the PDF file

Shipping charges

| Shipment | Costs | Times |

|---|---|---|

| Europe | FREE* | Delivery in 6 - 10 working days upon receipt of payment** |

| Non-UE | Charged to the recipient, according to the country of destination |

Customer Care

For more information on the products, on the purchase, for assistance and spare parts you can fill out the form.